The desk chair post, part 2

This was my desk chair.

I wrote about it before.

When I wrote about it before, I mentioned my concern that the much sturdier castors I fitted might end up breaking the no-metal-in-particular that cheap desk chairs swivel bases are made from. It broke a few months later.

Rather than fish another desk chair from a skip, I bought an entire swivel base assembly from Amazon for about £80. It turns out that not just the castors, but these entire assemblies are largely interchangeable between desk chairs. This thought had not occurred to me before! So, I did not have to "un-weld" the baseplate from the subframe as I had every previous time a swivel base had exploded on me. Just plop the old base plate and subframe on top of this...

...and my desk chair was fixed again. Simple!!

But, while I'm there...

Previously, I wrote:

I showed a photo of it to someone earlier today and they said "it needs arm rests". It doesn't need arm rests, but the fact someone thinks it needs arm rests means that it isn't the unquestioned best desk chair in the world.

It still did not have arm rests, so this time around I decided it was going to have arm rests. I had a pair of arm rests, salvaged from the previous donor chair.

Let's make some brackets! This time I bought (rather than salvaged) some steel for the purpose, for about £20. I still have some left over.

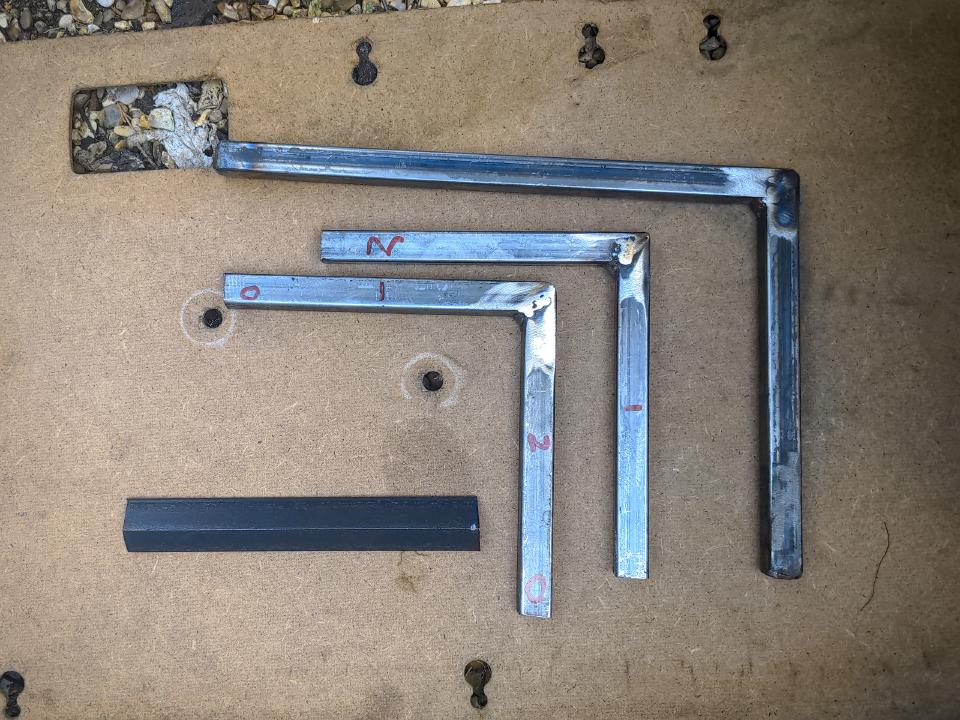

That turned into some smaller lengths of steel...

...which, via some dubious MIG welding and Jenolite satin black paint, turned into two slightly-wonky but almost presentable brackets for the arm rests.

Easy! (Just kidding, that took forever, because I am not all that good at this.)

As everything was dismantled (so that I could make a means to fix these brackets to the subframe), I figured I would give the subframe a cleanup and a coat of paint. It looked like this, resplendent in its original brown paint and marker pen assembly-guide scribbles from the first time I built it.

This subframe is an adapter plate between the car seat and the desk chair swivel base. It is almost always out of sight, so it didn't matter what it looked like. Still, I would never tidy it up it if I didn't do it now (the proof of this is that it has been unpainted for over a decade). This should have been just a coat of paint, but while I'm there...

...I was never very happy with those unfinished ends, either. They've never bitten me, and I've never seen them so I didn't mind them being ugly, but I always had the thought in my mind that they needed to be capped with something. This was as good a time as any to do it. So, some offcuts, some more dubious MIG welding, and some over-aggressive linishing to make the MIG welding look less dubious...

...and they look a bit better, if you don't really look at them. Which I won't! Because I'm sitting above them.

Still, the subframe that I never see now looks a lot more presentable. And when everything is bolted together...

...it has arm rests! Which was far more effort than it was actually worth, given that it never really needed arm rests. Especially when I came to use it and realised when setting the height for my arm rests I hadn't considered whether that height would allow it to fit under my desk...which meant chopping about 70mm out of the brackets the day after I assembled it all. But still, arm rests! And that, if nobody issues me some other challenge that makes me over-solve another problem that doesn't exist, should make it the unquestioned best desk chair in the world.