Overkilling the Rover P5, part 2: the gearbox

I know what you're thinking. It's something like "Lewis, a Rover P5's prehistoric manual gearbox will explode if you put 350 horsepower through it". And you're right!

Here was my gearbox. It's attached to my old engine here; I didn't separate them for the eBay auction because I couldn't be bothered. It was an ancient 4-speed manual. It is so old that it actually pre-dates the Rover P5; it's similar enough to the seventy-plus-year-old Rover P4's gearbox that most of the innards are allegedly interchangeable.

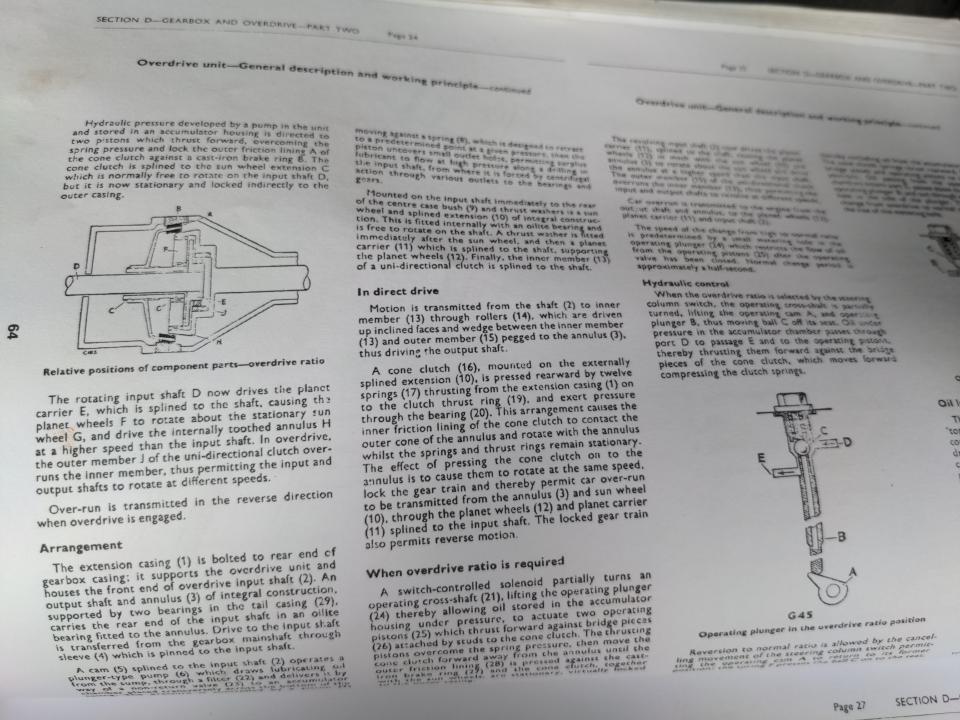

Over to the right of the engine and gearbox is a Laycock overdrive, which gives it a fifth gear for cruising.

The overdrive is high-tech for the 1960s; it's electrically-operated via a switch on the dash and had a lockout which stops it being used in fourth gear.

It's an amazing thing! It is far removed from the primitive Fairey units of the era, which used a mechanical lever to engage it, and an instructional plate in the interior telling you what gears you should use it in.

And before we go on, let's have a little digression back in time to "Lewis removes the old engine and gearbox".

To get the gearbox out, you must first remove the overdrive. To remove the overdrive, there is a ring of bolts, four or so of which can only be accessed through a small hole in the transmission tunnel. It's fiddly, it's time consuming, but it's doable - just one of those silly fiddly jobs you get on any car of any age.

Alternatively you could, as someone in this car's past decided, just fucking slice open the transmission tunnel, peel it back, and fold it back into place when you are done and not even bother welding it up because you're time constrained and nobody's going to notice and you are an idiot mechanic.

All I'm getting at, is that if anyone worried that I'm ruining a perfectly good P5 Mark 1A export CKD: I'm not. :)

Anyway, I no longer own any of that. The engine and box sold together on eBay. It made little money. I am comfortable with that fact, because it is going on to a new life in a Rover P4. It will be a substantial upgrade in the much-lighter P4 - that'll be a 115 horsepower engine in a 1400 kg car. Nice!

The transmission wasn't any good to me, because even if it could take the power I want to put through it (it absolutely will not), and someone actually made an adapter plate for it (nobody does), I wouldn't want to use it for a bunch of reasons, one of which is that parts are very scarce and expensive these days. Instead, I ended up with...

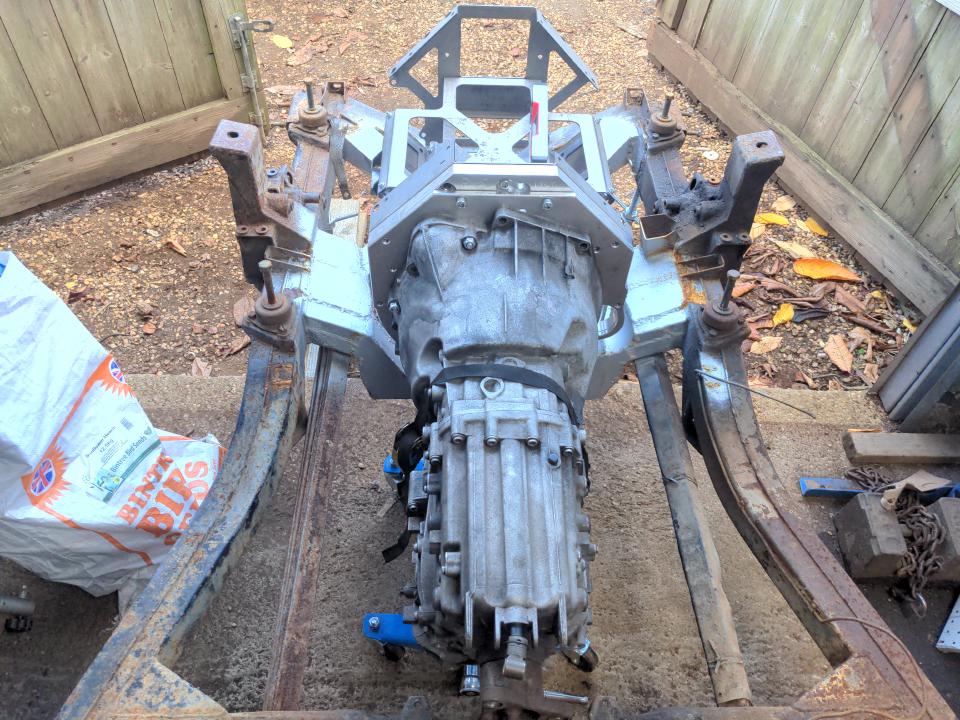

...a BMW GS6-53DZ HGD six-speed manual gearbox from a BMW 525D, and some shiny things. How did I get here?

Above all, I wanted a manual transmission. I don't intend to ever buy a car with an automatic transmission, and I'm definitely not going to build one. If I liked automatic transmissions I'd have lots of bolt-on options, some of them quite cheap, but I don't, so I don't.

With auto boxes written off, the bolt-on options (other than some mad Quaife sequential and yes I did seriously consider this) are exactly two: the five-speed Tremec TKX and the six-speed Tremec T56. You can probably find a T56 at a scrapyard, if you live in the United States where the LS engine was born and cars with LS engines were sold by the millions. That is not where I am from, and a T56 is a specialist item over here. You can get them new in the UK, but they run about £4000 before you've bought a bellhousing for it. The TKX is only slightly cheaper.

I'm not building this car on the smallest possible budget. That ship sailed two seconds after I decided to do an LS swap in the UK. But if I can save several grand without compromising anything I will, because that gives me more money to spend on takeaways and more car parts.

So, the BMW gearbox. While I don't want a four-speed gearbox, I have no particular desire for a six-speed gearbox; I am not building this car for motorway-mile high-scores done quietly and economically. I bought this because it is a reputedly strong gearbox. It is rated for 391 lb-ft of torque (or 530 newton metres, the "53" in the name). Most likely the GS6-53DZ is good for much more torque than that (evidenced by the drifters routinely not blowing them up). I should have headroom if I do something silly like bolting a turbo to the LS1 which absolutely is not occupying my every waking thought right now.

As well as being a strong gearbox, it is a strong gearbox I can get cheaply. The HGD-suffix gearboxes aren't as plentiful as the others, but they're not hard to find for less than £500. That means I can justify buying a spare, for when I inevitably destroy it doing massive smoky burnouts. And if anything does go wrong, it's not hard to get parts for them nor to find anyone to work on them in the UK.

To get any of this to work with the LS engine, I got the PMC Motorsport adapter kit. Those are the three shiny bits you see in the photo above. To the left is a gorgeously-machined plate which bolts to the BMW gearbox. On the right is another gorgeously-machined plate which bolts to the LS engine. These two bolt together to mate the engine to the gearbox. In the middle is a custom flywheel, which bolts to the LS1's flex plate/starter ring.

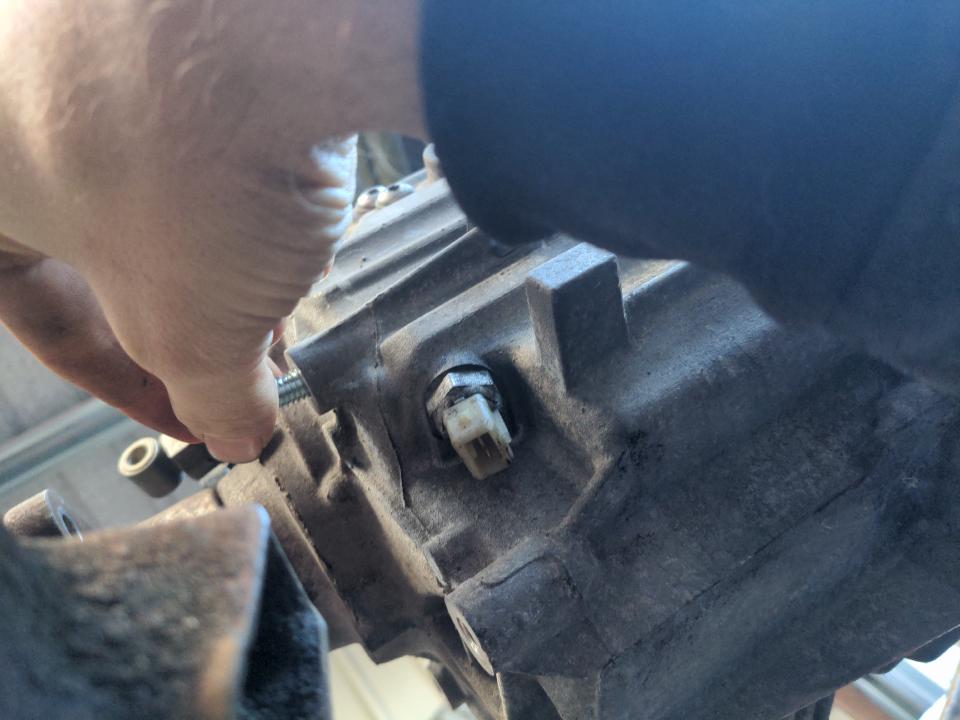

I will need to make a minor modification to the gearbox (the guide tube needs shortening), and there are more parts to be acquired before this is a working transmission setup, but I'll deal with that later. Let's get out the trusty caravan stands and transmission jack and find out how this gearbox doesn't fit the car, and what we can do about that fact.

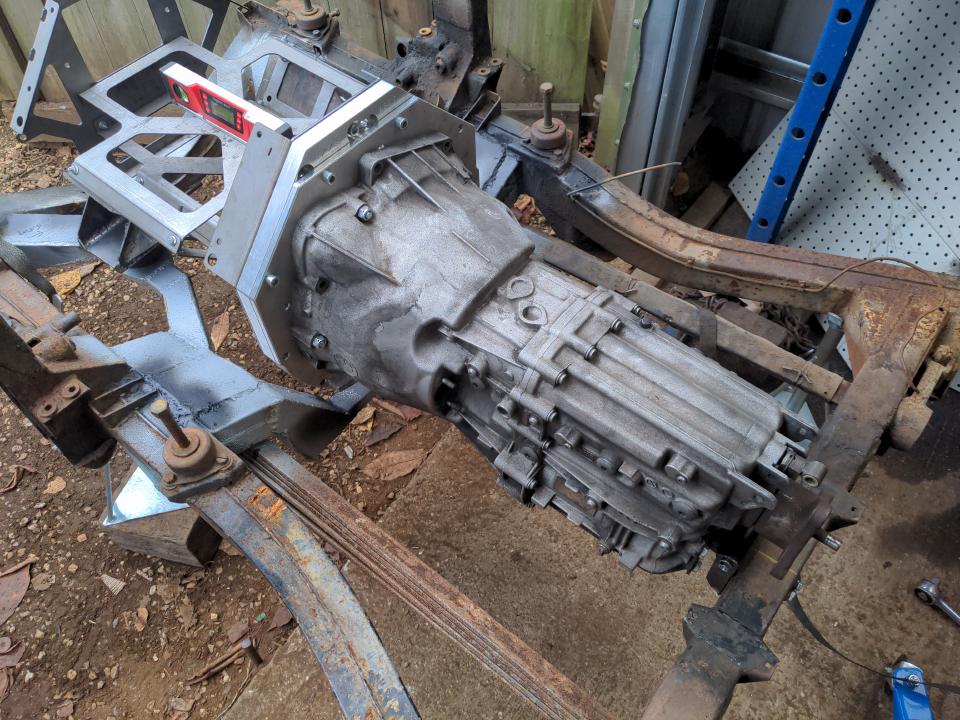

The good news is that the body of the gearbox fits within the subframe! My fear was that I might have to cut out and reshape the rear crossmember of the subframe to do this, but that isn't necessary. The body of the gearbox clears every part of the subframe, and the output spider clears the rear of the subframe. It's tight, but that's another way to spell "fits"; nothing I actually need hits anything that can't be modified.

The BMW OEM rear mounts are entirely negotiable. It's a three-part system which is very light, but also very large.

There's no room to fit it behind the gearbox in the Rover P5 subframe. This would require cutting out part of the rear-most crossmember - a thing I wish to not do. And even if I could use it, it has rather too much flex for my tastes. It makes sense for minimising noise and vibration in a daily-driven car, and does not make sense for me.

In designing a new mounting, it would be really easy to design something with the access I have now, which would be impossible to fit it when it was on the car. For example, the four bolts on the back of the gearbox are really easy to get to - when I'm working with a subframe sat on caravan stands in my workshop. They're a lot more fiddly to get to from underneath, which is how I will be accessing them when fitting the gearbox to a subframe bolted to the car.

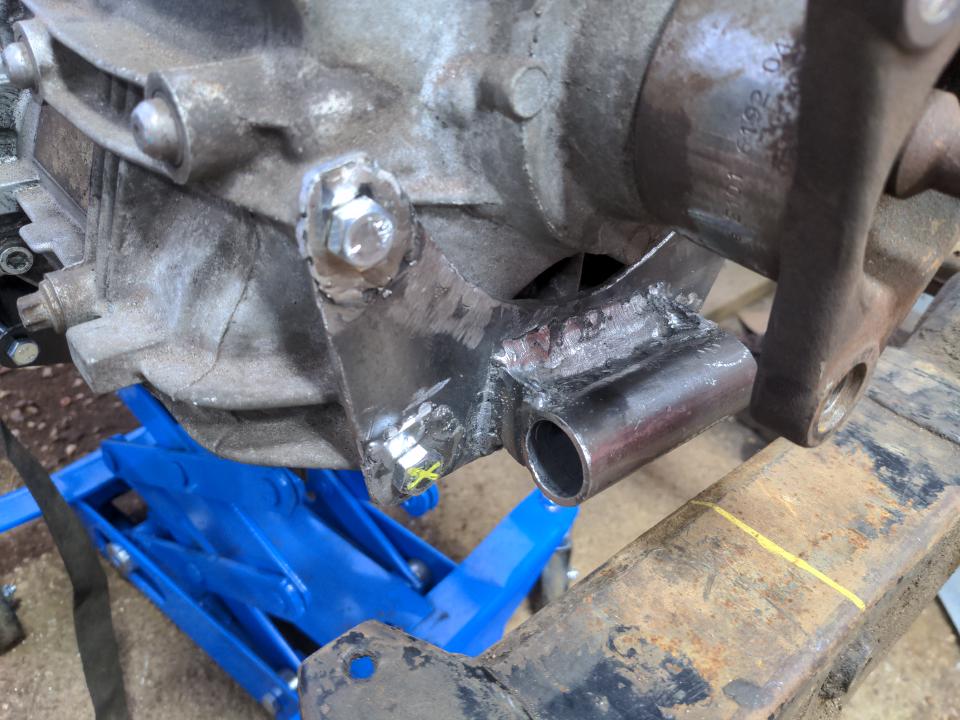

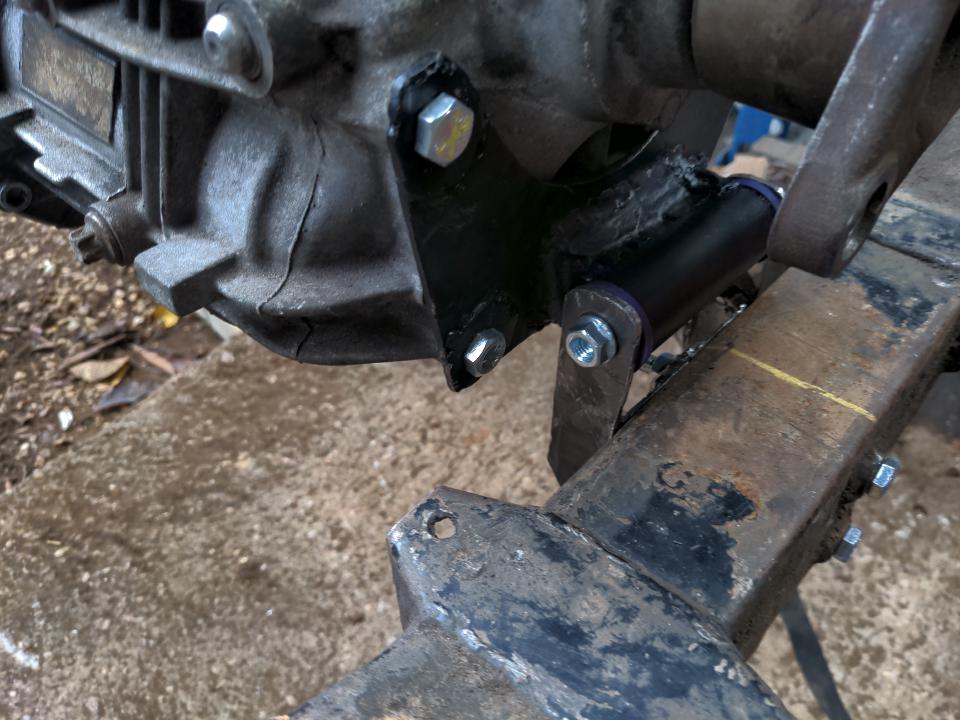

So with some thought (and a stroke of genius from Maurice), I came up with a two-part mounting which is a lot simpler and stiffer than the OEM mounting. Here is part 1.

I copied the hole spacing and the vague shape from the original BMW gearbox mounting and traced it onto 3mm steel plate. I got the holes not quite right the first time; I needed to relocate one of them further out-board, and rather than move that one out all the way I decided to relocate all of them only a little to compensate, and reinforce those areas with welded-on washers.

On that plate is a piece of 28mm ID steel tube, separated from the plate with some random bit of angle iron I had kicking around (probably 20mm). That isn't really there for spacing. Instead, it made it much easier to get the tube aligned perfectly level (± my sloppiness) when I stuck all of this together.

This bolts to the back of the gearbox, and will be bolted to the gearbox when I fit it into the car - solving the problem of those four bolts being fiddly to get to from underneath.

The other half of this re-uses the original two holes in the subframe for the rearmost gearbox mounting bracket on the P5's subframe (but I drilled these out to accept an M8 bolt, only a fraction larger than the original Imperial 5/16). And I took the original P5 rear mounting bracket...

...and Frankensteined it with more 3mm plate into whatever the fuck this is:

These two parts join together via a generic 90mm Powerflex top hat bush which I actually bought for a different sub-project on the car (tell me if you guessed what that might be). When it all bolts together, it looks like this:

This, I think, is a rather neat solution to the problem. It fits. It's simple. It'll actually be accessible in situ. And it'll give me enough flex to stop the vibration driving me nuts (and hopefully enough to stop the gearbox from shaking itself apart), unlike a solid mount.

And with everything else bolted up...

...I get another another milestone: a (stunt) Chevy engine and BMW gearbox bolted into a Rover subframe with no outside support.

And that, is enough car for now. :) See you next time.

Part numbers from this post:

- Gearbox: BMW GS6-53DZ HGD / 23 00 7 522 205 (ZF 1067 401 060)

- Gearbox adapter: PMC A-LS-HGD-240

- Bushing: Powerflex PF99-101

- Stunt engine: Speedway Motors 12640748

- Transmission jack: Draper 09021

- Steel from Thomas B. Bonnett