A quick, cheap fix for a dead Clarke MIG welder

TL;DR: test your power selection switches.

This is my Clarke 151EN. I've written about it before.

It's an upgraded hobby MIG that I've been using for a while. I doubt it was designed for the miles I've been putting on it, but I couldn't justify replacing it with one of the fancier machines because it does everything I need.

Until it stopped working! It not working manifested as what appeared to be no wire feed. I pressed the trigger, and no wire came out.

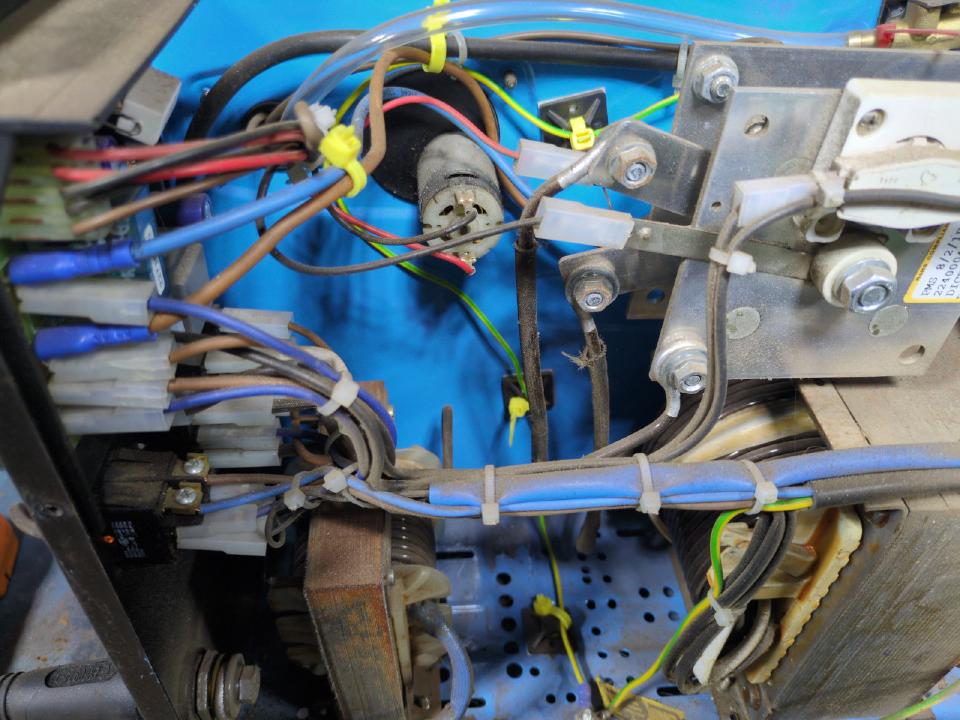

Rather than write the machine off, a little dive into the spicy side of the welder and poking around with a multimeter...

...showed that the wire feed is not separately triggered from the welding current. Rather, the switch on the torch activates the welding current, which in turn drives the wire feed. It makes sense, and I think that's a clever way to reduce the component count. If the wire feed wasn't working, the likely immediate cause was that there was no welding current.

That meant that either my transformer was dead or my transformer was not getting any current for some reason. And my spidey sense (basically me looking at some wires and pretending I know what the fuck I am doing) told me that I should look at my power selection switches. They are the white ones below, not the big orange on/off switch. Some lower-end welders don't have all three switches.

Here's what one of those switches looks like once you remove it.

To test these switches, use a multimeter in continuity mode. Put one probe on the common pin in the middle, and another on one of the other two pins. One of the two positions of the switch should cause continuity to be achieved. Then test the middle pin and the other pin which you didn't test the first time, and flip the switch to the position you didn't get continuity on for your first test; again, you should have continuity. If you don't, your switch is dead, and that is causing your welder to not work.

Mine was dead! Fortunately I had a couple of spares kicking around from dismantling another welder. If you don't dismantle welders for fun these only cost a few pounds. A web search for JD03-F1 will probably turn up a good candidate for a replacement part.

Anyway:

I replaced the faulty switch, and it worked again. Actually I replaced two switches, because the middle 2/3 switch had been stuck on 3 for a while and I just never found a good enough reason to replace it.

So, if your welder appears to be dead and it's one of these basic welders with two-position power selection switches, test those switches first. It's one of the easiest things to test, so you won't lose anything by trying, and it's probably the cheapest part to replace, so you won't pay much to fix it. I hope these thought are useful to someone else.